Hwatsing Technology blazes new trails in Chinese innovation

2017-07-20

Hwatsing Technology Co Ltd, a company based in Haihe Science and Technology park in the city of Tianjin, has received the 2016 Tsinghua Industry Top 10 Innovation Project award for its 28-14 nm Chemical Mechanical Polishing (CMP) equipment, technology and supporting materials.

Three years ago when Hwatsing Technology's team, a group of trailblazers from China's top university and academic institutions, came to Tianjin, they just had one goal – to advance commercial use of the CMP technology and equipment developed by China.

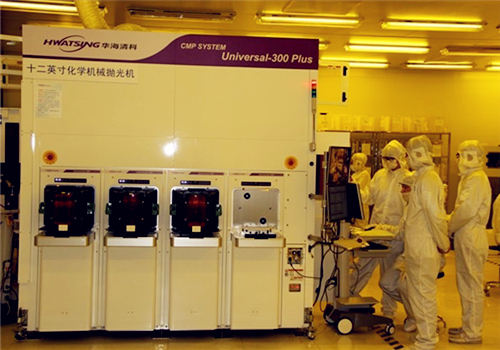

CMP equipment

The research path of CMP equipment

In 2008, Tsinghua University Friction National Lab began to conduct the research and technology development of CMP under super-low pressure. Two years later, Tsinghua University developed the first CMP sample machine. After multiple times of technological upgrading and iteration, the university succeeded in developing the 12-inch dry-in/dry-out CMP equipment in 2012, which is able to reduce surface roughness to less than 1nm on 12-inch wafer and reduce nonuniformity to below two percent. Generally, the surface roughness of a cellphone screen is around 20nm.

This equipment has made a milestone breakthrough in China's development of integrated circuit manufacturing equipment.

CMP equipment technology, along with photoetching, etching, ino implantation, and film growth, makes the core of the integrated circuit manufacturing techniques.

Researchers conduct research work in front of CMP equipment.

The CMP technology is the only one simultaneously enabling planarization of the whole and of individual parts, avoiding surface damage, roughness, and nonuniformity through other polishing techniques.

CMP technology commercialization

CMP is widely used in polishing an array of products, including cell phone screens and the mirror-like aluminum alloy back plate. China's polishing technology is advanced in many areas, but before the development of Hwatsing's CMP equipment, it was still drawing a blank in the field of integrated circuit manufacturing.

To advance China's CMP technology in the semiconductor industry, Hwatsing Technology developed the first commercial 12-inch dry-in/dry-out CMP equipment—Unisersal-300—in 2014, bringing Tsinghua University's technological achievement into the market.

The equipment was sold to the Semiconductor Manufacturing International Cooperation (SMIC), one of the leading semiconductor foundries in the world, after passing an assessment. The equipment has managed to fill the gap in China's CMP equipment used in the field of integrated circuit manufacturing. So far, it has processed more than 60,000 silicon pieces.

The delivery ceremony of the CMP equipment to SMIC

In February 2017, Hwatsing Technology completed the installation, debugging, and pilot production of its second CMP equipment in the SMIC, in only 78 days.

Innovation is at the core of success

"Self-innovation is the key for Tsinghua University and Hwatsing Technology," said Wang Tongqing, assistant of the general manager at Hwatsing Technology.

"We chose the final solution from dozens of proposals after many rounds of discussions," Wang added. "We created our own unique CMP system without IP conflict. Thus, our products have gained wide recognition from clients."

So far, Hwatsing Technology and Tsinghua University have had more than 150 CMP technology-related patents and have primarily built a CMP equipment and technology system featuring technological advantage and intellectual property rights.

The celebration of the second CMP equipment on production of over 100 silicon pieces within 78 days

In addition, a professional team with expertise is also one of the important elements that have contributed to the success. Hwatsing's team includes research fellows from Tsinghua University and experts from home and abroad. The industry-academia-research cooperation between Tsinghua University and Hwatsing Technology continuously fuels technology advancement.

An official document was issued in 2015 that outlines the coordinated development of Beijing, Tianjin, and Hebei province. Tianjin was given the role to develop the advanced manufacturing industry, by, for instance, developing high-end equipment and electronics information. National policies have also provided Hwatsing Technology with more opportunities for further development.

Facebook

Facebook WeiXin

WeiXin CONTACT US

CONTACT US

Tsinghua Holdings works hard for better ecological environment

Tsinghua Holdings works hard for better ecological environment