China's innovative technology tackles the problem of train security inspection

2017-07-25

Terespol, a city on the eastern border of Poland and at the intersection of the Amber and Silk roads, has been equipped with a "made-in China" train container inspection system, detecting cargo transported along the route that connects China and Europe.

Developed and produced by Nuctech Company Ltd, a subsidiary of Tsinghua Tongfang affiliated to Tsinghua Holdings, the security inspection equipment is the first and only inspection device that can be used to scan train containers across three railway tracks.

Nuctech's train container security system used in Terespol, a city on the eastern border of Poland

This equipment has a detector tower that stands around 20 meters tall, and is 22 meters from the farthest trail track. It can thoroughly scan and inspect goods inside the train, even while it travels on the third farthest railway track at speeds reaching 60 kilometers per hour.

The core technology of the equipment-the standing wave electron linear accelerator technology based on a solid state modulator-is unique to China, and is a significant improvement to customs clearance efficiency.

In 2009, the engineering physics department of Tsinghua University and the accelerator R&D team from Nuctech started developing the solid state modulator project to work out a smaller, lighter, more stable, and more reliable accelerator that is easier and faster to scan.

After hundreds of rounds of discussions, trials, analysis, and comparison, the best scheme won out.

It was the seemingly paranoid perseverance that helped achieve the success in the standing wave electron linear accelerator technology.

In 2014, the product with this technology was finalized in its design, and it was produced in batches in the following year. This technology then became widely used in the imaging systems of all kinds of goods and vehicles security inspection equipment, nondestructive inspection systems, and electron beam irradiation sterilization systems.

This technology also made it possible to develop the world's most advanced cross-three rail train inspection system. In the past, the inspection equipment had to be equipped on only one railway and was only able to carry out inspection when a train slows down to pull in.

"The solid-state modulator to the original linear one is what a smart cellphone is to a feature phone," said Liu Yaohong, deputy head of the joint research institute of Nuctech.

In addition, all the operation parameters are easy to change and adjust through programming, which can also be achieved through remote operation. The parameters showing the equipment's state of work can be transmitted to the maintenance center for real-time tracking.

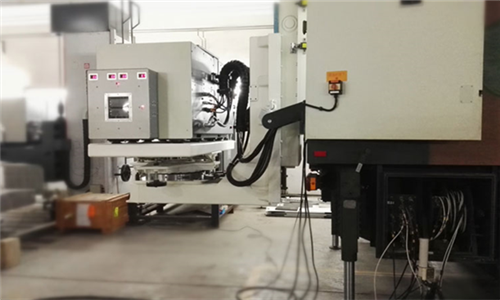

The inspection system manufactured by Nuctech

With this innovative product, Nuctech had amassed 80 percent of the global market for train inspection systems by the end of 2016.

In addition to train inspection systems, other inspection products manufactured by Nuctech have been sold to more than 150 countries and regions around the world. The company has the biggest market share in Africa and more than half in America. Over 85 percent of European countries have purchased security inspection equipment from Nuctech. The company's large-scale container inspection equipment has taken the lead in the global market share for many years.

To gain such exciting achievements is not an easy thing.

"The inspection industry bears many risks. The market capacity is not big, but needs many technological and capital investments," said Li Yuanjing, vice president of Nuctech.

The inspection industry sets high entry standards for potential market access and started much later in China than it did in Europe and America. In 1995, when smuggling was rampant in China, customs needed more advanced inspection systems to strengthen their work and crackdown on smuggling. Thus, Nuctech was established, under the leadership of professors from the engineering physics department of Tsinghua University.

"The advantage of Nuctech's core technology in inspection system over the past 20 years is attributed to our scientists, as they are the ones giving Nuctech its competitive edge," Li Yuanjing added. "R&D costs are enormous every year."

Nuctech has been implementing industry-academia-university cooperation with Tsinghua University, serving as a bridge to inject the university's state-of-the-art scientific and technological findings into products.

"Looking back at Nuctech's journey in the past 20 years, we can see that sometimes, the most difficult decisions eventually lead to our best achievements," Li said.

Facebook

Facebook WeiXin

WeiXin CONTACT US

CONTACT US

Tsinghua Holdings works hard for better ecological environment

Tsinghua Holdings works hard for better ecological environment